control systems

VME based master control system

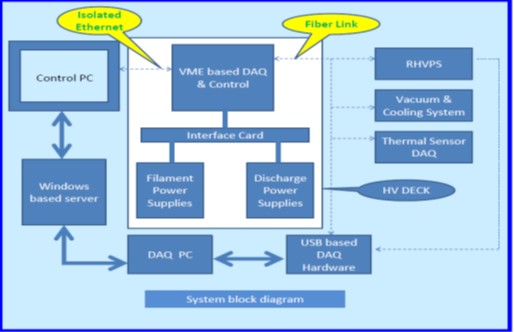

Block Diagram for Control System VME based control system which synchronizes operation of all subsystems (E.g. all Filament heating, Discharge and acceleration power supplies) and perform master control of NBI machine operation. The VME based CPU has been loaded with real time operating system (Vx-works). In the VME chassis, several modules are used to perform various tasks, like analog signal acquisition, analog signal generation, digital commands and status information. A Windows-NT based control PC, located in NBI control room is connected to VME based control system for the operator interface.

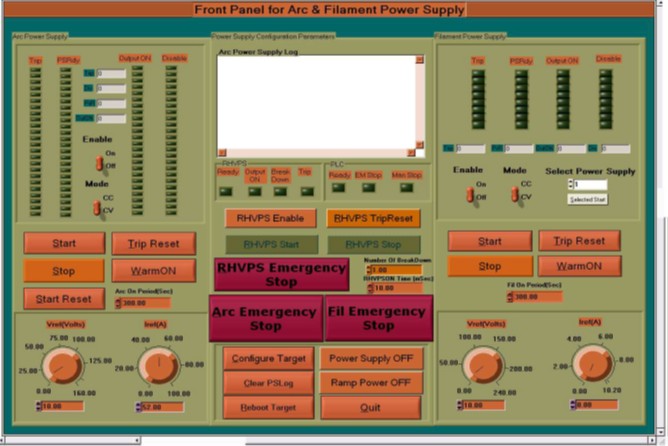

Front panel for power supply Control

VME based control system |

PLC based control system

Block Diagram for PLC Control System PLC based control system A Programmable Logic Controller (PLC), controls and acquires data of vacuum system (VS), Gas feed system (GFS),cooling water system (CWS) and cryo condensation pump I&Cs. Operation and control of various I&C components is automated as per functional analysis. VS has combination of root rotary and TMP pump to achieve required pressure in vessel during beam extraction in low gas feed mode and other experiments as well. Various vacuum measuring gauges are installed at different locations to measure vacuum inside the vacuum chamber as per different pressure ranges and expected gas compositions. Vacuum pumps are switch over by operation of isolation valves in automated way by PLC. A total of 16 digital and 8 analog I/Os being control and monitor for VS. |